The Right Rotary Slitter Tooling

For Any Job

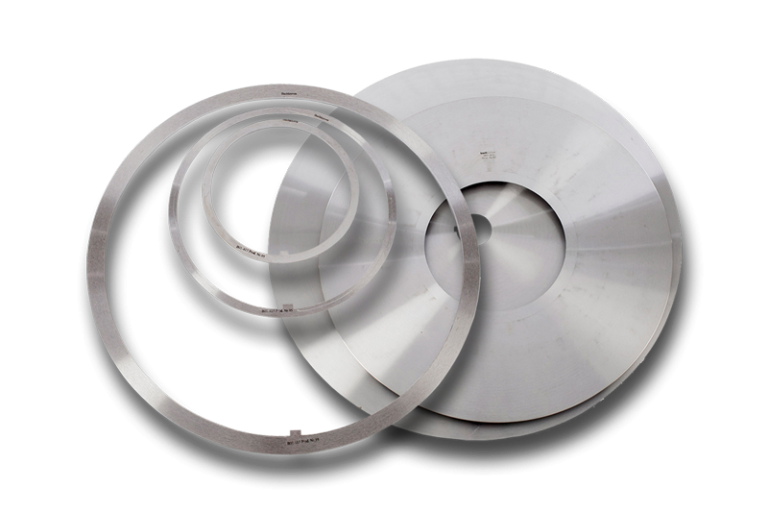

Rotary Knives

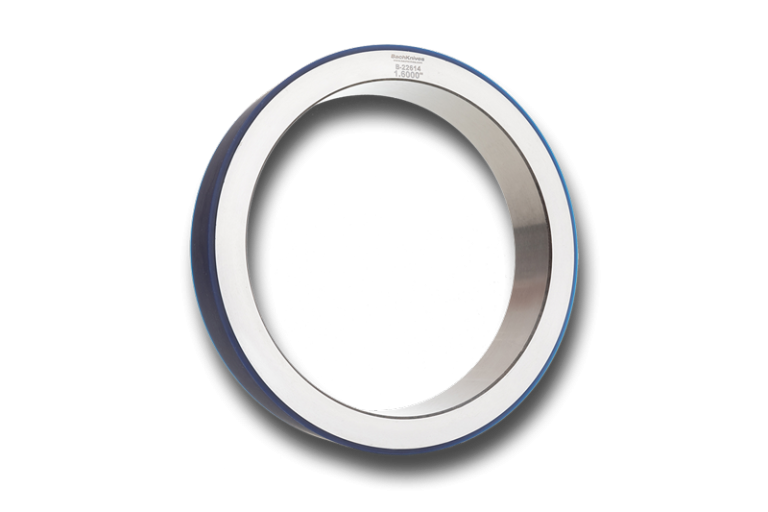

Rotary Spacers

Stripper Rings

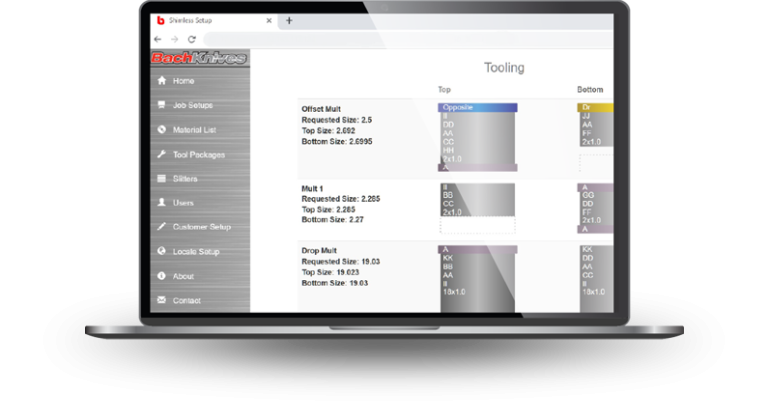

Shimless Tooling Systems

Ultra-Precision Quills

Hydraulic Clamp Nuts

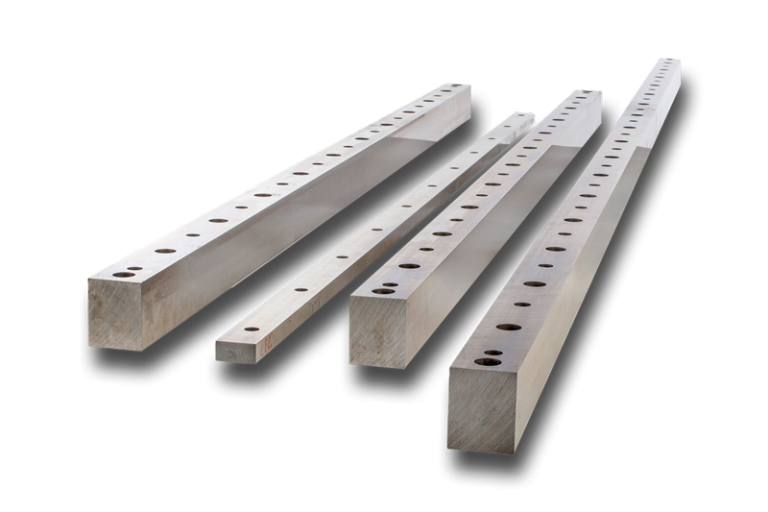

Shear Blades

Separator Plates/Core Disc Drive

Over-Arm Separator Tooling

Scrap Choppers

Friction Saws

Capabilities

Knives

Our slitter knives are manufactured using state of the art materials and the latest technology and production techniques. We start with the highest quality European forged material, vacuum harden and triple temper to Rockwell held to ±1, then finish with lapping and polishing to produce the finest metal slitter knives.

We offer the best-suited and successful grades for slitting and shearing HSLA, AHSLA, Duplex©, stainless steels, nickel alloys, copper, brass, titanium, aluminum, hot rolled steels, phosphorus alloys, bronze, and clad metals.

Spacers

Our spacers are manufactured from the finest through-hardened tool steels with the same precision tolerances as our knives. We also provide light weight executions in polyamid and tool steel. All spacers are clearly etched for easy identification.

Alloys

Forged Hermanite Alloys

Carbide with BachKnives’ Mirror Finish

Powder Metal

Forged Tool Steel (D2, M2, T1, H13, etc.)

Stainless Steel

Aluminum

Precision Tolerances

Thickness +/-0.000040″ (+/- 0.000020” can also be achieved)

Flatness within 0.000080″

Parallelism better than 0.000080″

2-3 microinch (0-1 can also be achieved on carbide)

H5 bore tolerances where necessary

Hardening

Conventional heat treating processes

Vacuum treating processes

Triple tempering